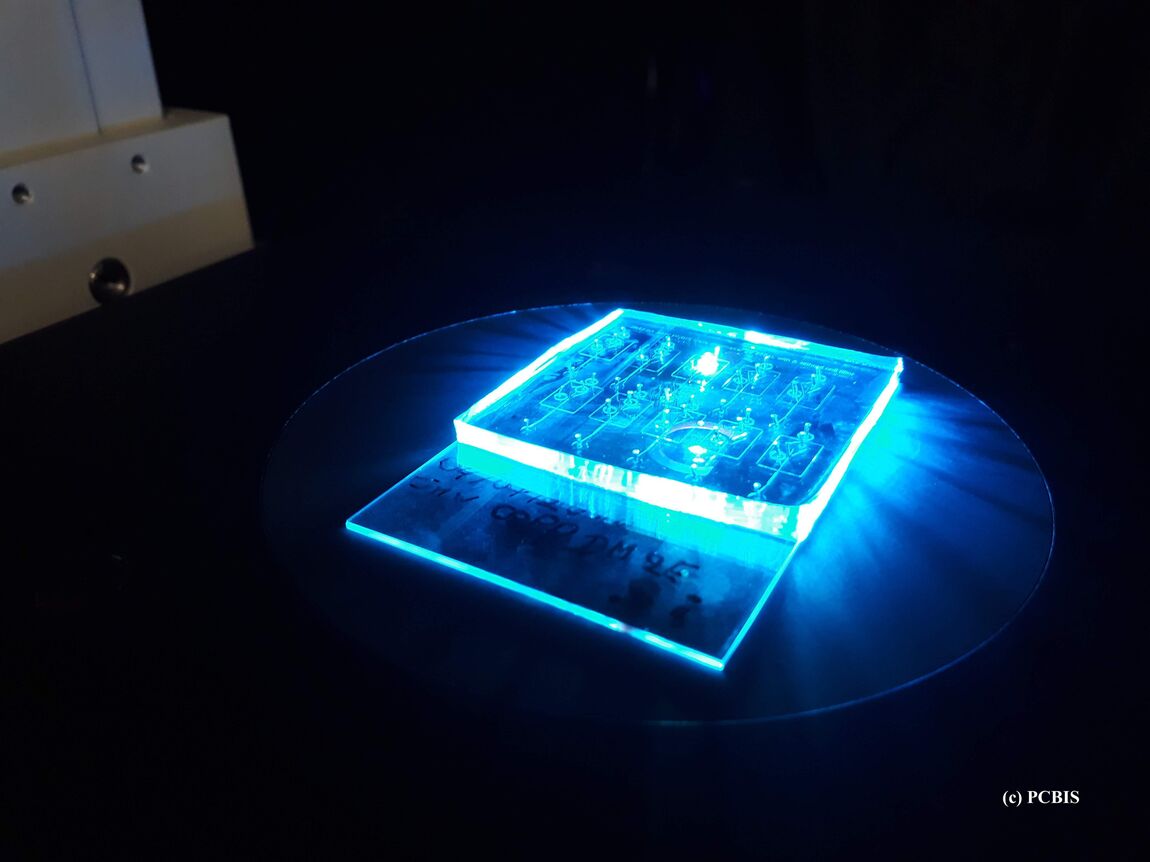

Microfluidics department

The microfluidic department aims at the miniaturization of screening tests in PDMS microfluidic chips in order to reduce the amount of reagents and cells used, as well as to increase the speed of analysis (ultra-high throughput screening). This is done, in particular, to offer new tests using small samples, such as patient cells. We are also working on reducing animal testing through the development of microfluidic devices such as organs-on-a-chip.